Cost Structure and Profitability Analysis of Integrated Ammonia-Urea Manufacturing Plant: A Detailed Cost Model

_11zon.webp)

What is Integrated Ammonia-Urea?

Urea is a nitrogenous compound produced in living organisms as a by product of the metabolism of protein degradation. In industrial and agricultural use, urea is a synthetic compound produced on a large scale for use as a fertilizer.

Key Applications Across Industries:

Urea is a critical source of nitrogen that helps to enhance plant growth and development. Its high content of nitrogen makes it popular in the agricultural sector and serves as a concentrated, readily available source of nitrogen for crops. Besides being a fertilizer, urea also has several industrial uses, such as the manufacture of adhesives and some resins, as well as plastics.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global integrated ammonia-urea market was valued at US$ 142.1 Billion in 2024, growing at a CAGR of 8.6% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 3.9% from 2025 to 2033, reaching a projected value of US$ 202.4 Billion by 2033. The market is growing mainly because of the growing world population and the resulting need for food, which forces the agriculture industry to rely on urea as a crucial nitrogen fertiliser because of its high nitrogen concentration.

In addition, the market is growing because of the biofuels industry's thriving expansion, which uses urea to produce urea-formaldehyde resins for use in biofuel production processes. Furthermore, urea, which is well-known for its support of ecologically friendly farming methods, is being adopted because of the increased emphasis on sustainable agricultural practices and the necessity for effective nutrient management. This is another important driver driving growth. Accordingly, advancements in technology within the urea production processes, such as improvements in more energy-efficient and environmentally friendly production techniques, which raise the efficiency of production, thereby reducing the cost, are the driving factors of the market.

Case Study on Cost Model of Integrated Ammonia-Urea Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale integrated ammonia-urea manufacturing plant in Reynosa, Mexico.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 650,000 tons of integrated ammonia-urea per year.

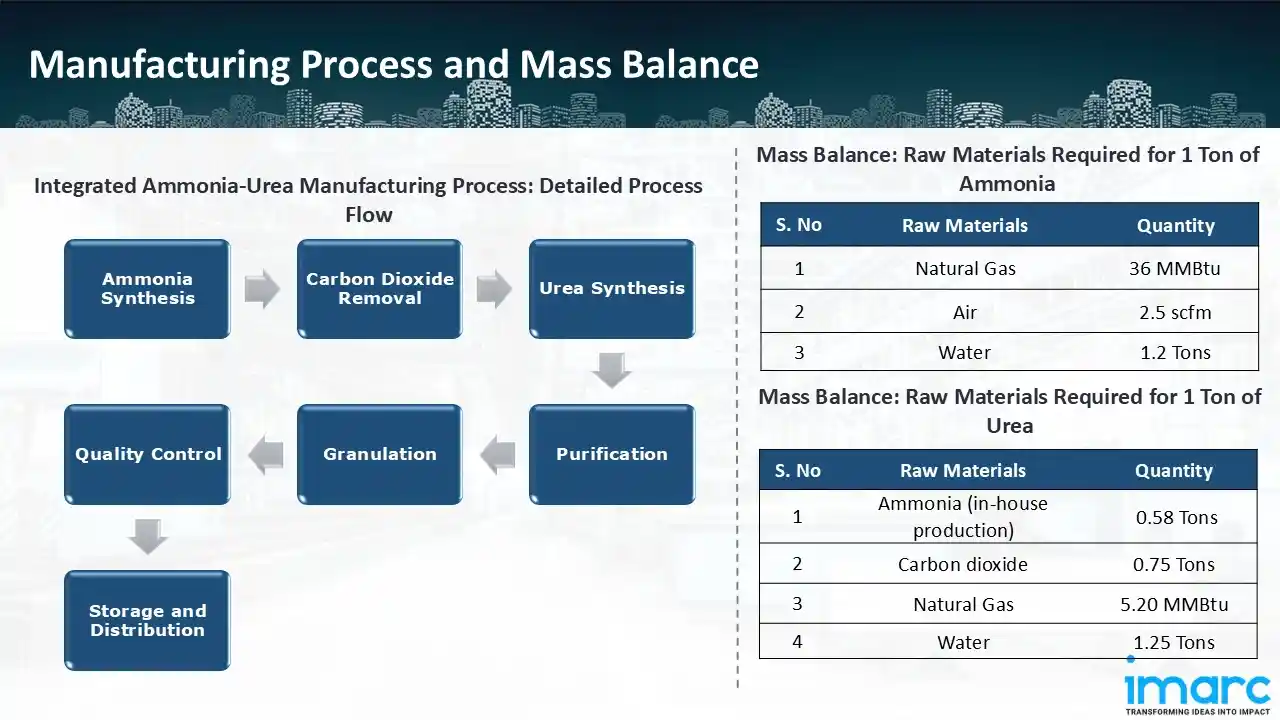

Manufacturing Process: The first step in the Integrated Ammonia-Urea manufacturing process is ammonia synthesis, in which airborne nitrogen combines with hydrogen (often from natural gas) to form ammonia (NH3) in the Haber-Bosch process at high temperatures and pressures. The next step is to remove carbon dioxide, which is a byproduct of producing hydrogen. This CO2 is caught and utilized in the urea synthesis process, which produces urea (CO(NH2)2) and water when carbon dioxide and ammonia react under extreme pressure to create ammonium carbamate. To guarantee a high-purity end product, the crude urea is purified to eliminate water and unreacted components. Granulation transforms the purified urea solution into solid granules or prills, which facilitate handling, storage, and transportation. Prior to distribution, quality control verifies that the urea satisfies industry requirements for moisture content, granule size, and nitrogen content. The final product is then moved to distribution and storage facilities, where it is packaged and sent for use in industrial applications such as adhesives and resins, as well as in agriculture as a high-efficiency nitrogen fertilizer.

Mass Balance and Raw Material Required: The primary raw materials utilized in the ammonia and urea manufacturing plant include natural gas, carbon dioxide, water, and air. To produce 1 ton of ammonia, around 36 MMBtu of natural gas, 2.5 scfm of air, and 1.2 tons of water is required. Additionally, to produce 1 ton of urea, 0.58 ton of ammonia, 0.75 ton of carbon dioxide, 5.2 MMBtu of natural gas, and 1.25 tons of water is required.

List of Machinery:

The following equipment was required for the proposed plant:

- Desulfurization Unit

- Natural Gas Compressors

- Primary Reformer

- Steam Methane Reformer (SMR)

- High-Temperature Shift Converter

- Low-Temperature Shift Converter

- Absorber and Stripper Columns

- Methanator

- Ammonia Converter Reactor

- Heat Exchangers

- Ammonia Separator

- Recycling Compressors

- Ammonia Storage Tanks

- Ammonia Refrigeration System

- Ammonia Feed System

- CO2 Feed System

- Urea Reactor

- Ammonium Carbamate Decomposer

- High-Pressure Stripper

- Evaporation Unit

- Crystallizer or Prilling Tower

- Cooling System

- Ammonia Recovery System

- CO2 Recovery System

- Urea Granule/Prill Storage Silos

- Conveyor Systems

- Dust Collectors

- Water Treatment Plant

- Steam Boilers

- Cooling Towers

- Distributed Control System (DCS)

- Compressors and Pumps

- Heat Exchangers

- Pressure Relief Valves

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

_11zon.webp)

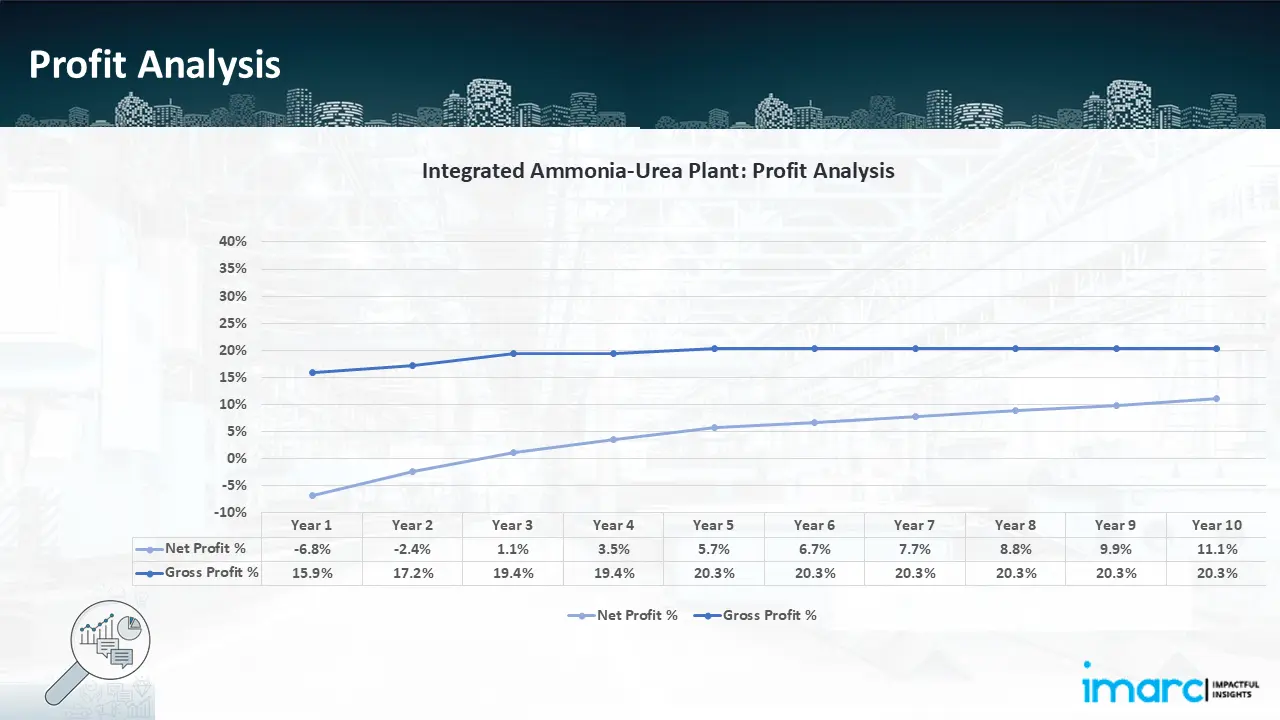

- Profitability Analysis Year on Year Basis: The proposed integrated ammonia-urea plant, with a capacity of 650,000 tons integrated ammonia-urea per year, achieved an impressive revenue of US$ 170.9 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising till Year 5 and staying steady from year 5 to year 10. Gross profit improved from 15.9% to 20.3%, and net earnings rise from a negative of 6.8% to a positive 11.1%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our integrated ammonia-urea manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 650,000 tonnes of integrated ammonia-urea annually. Our commitment to offering precise, client-centered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In December 2024, NTPC Ltd. announced considering taking part in the SIGHT scheme in order to supply green ammonia from its ambitious Pudimadaka green hydrogen hub through its subsidiary NTPC Green Energy, specifically to the nearby fertiliser plants of Coromandel International Ltd. and Madras Fertilisers Ltd.

- In December 2024, Indian fertiliser company IFFCO created nano NPK. Government permission is pending for the new granular product. It will be made in IFFCO's Kandla factory. It will cost Rs 950 for a 5 kg bag. This invention seeks to lower the use of DAP and urea. IFFCO has already introduced nano liquid DAP and nano liquid urea. The corporation made significant investments in the technology of nanofertilizer.

- In November 2024, National Fertilisers Limited (NFL), a state-owned company in India, declared its intention to produce nano liquid urea. NFL stated in a regulatory filing that it will be utilising state-of-the-art nanotechnology to introduce its most recent and highly effective nano urea variation at its Nangal plant as part of its excursions into the nano urea market.

- In August 2024, Woodside Energy, a global energy company based in Australia, said that it has reached an agreement with clean fuels-focused producer OCI Global to acquire the Texas-based low carbon ammonia plant for US$ 2.35 Billion, citing long-term industrial demand growth for cleaner energy solutions.

- In May 2024, the first biomass-balanced ammonia and urea products from BASF were shown. After launching its initial BMB ammonia and urea products, BASF now offers biomass-balanced (BMB) options across its ammonia value chain. The wide range of products includes ammonia anhydrous BMBcert, ammonia solution 24.5% BMBcert, urea prills BMBcert, urea solution 40% BMBcert, and urea solution 45% BMBcert.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104